Our Services

Our Products

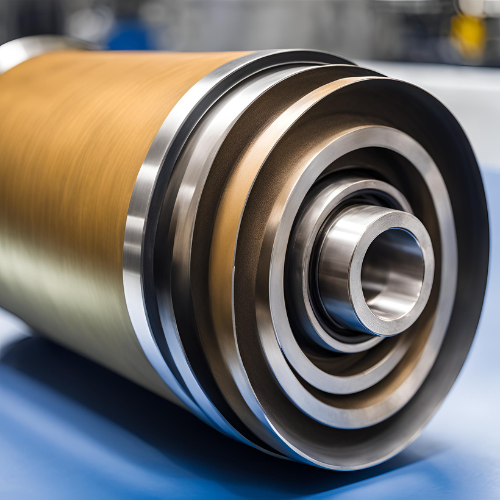

Offset Printing Rollers

Our Offset Printing Rollers are engineered to provide exceptional performance and longevity in the printing industry. With precise engineering and high-quality materials, these rollers ensure smooth and consistent ink transfer, resulting in sharp and clear prints.

Benefits:

Enhanced print quality

Long-lasting durability

Efficient ink and water distribution

Newspaper Printing Rollers

Our Newspaper Printing Rollers are specifically designed for high-speed newspaper printing applications. These rollers deliver excellent performance and durability, ensuring clear and consistent prints even under demanding conditions.

Benefits:

High-speed performance

Consistent print quality

Reduced downtime

Gravure Printing Rollers

Our Gravure Printing Rollers are crafted for precision and reliability in gravure printing processes. These rollers provide excellent ink transfer and durability, making them ideal for high-quality and high-volume printing applications.

Benefits:

Superior ink transfer

High durability

Precision engineering

Plywood Rollers

Our Plywood Rollers are designed to withstand the rigors of the plywood manufacturing process. These rollers provide reliable performance and longevity, ensuring efficient and smooth operations in plywood production.

Benefits:

Enhanced durability

Consistent performance

Efficient material handling

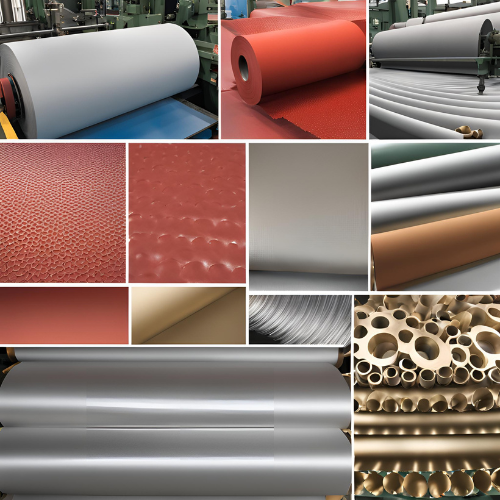

Exterior Material Coating Rollers

Our Exterior Material Coating Rollers are tailored for various applications in the production of exterior building materials. These rollers are built to deliver consistent performance and durability, ensuring high-quality output.

Benefits:

Reliable performance

High durability

Consistent quality

Steel Plate Rollers

Our Steel Plate Rollers are engineered for precision and durability in steel plate processing. These rollers provide excellent performance and longevity, ensuring efficient and smooth operations in steel plate manufacturing.

Benefits:

Enhanced precision

Long-lasting durability

Efficient material handling

Textile Rollers

Our Textile Rollers are designed to meet the specific needs of the textile industry. These rollers provide excellent performance and durability, ensuring smooth and efficient operations in textile manufacturing processes.

Benefits:

Superior performance

High durability

Consistent quality

| Sr. No. | Rubber Roller | Hardness (Shore A) | Grade | Properties |

|---|---|---|---|---|

| 1 | Ink Roller (Oil Based Inks) | 10 ~ 60 | N+P ANT | Low heat buildup, Dimensional stability, Ink resistance, Ink transferability, Abrasion resistance |

| 2 | Ink Roller (UV & Oil Based) | 20~50 | ANT COMBI | Low heat buildup, Dimensional stability, Ink resistance, Ink transferability, Abrasion resistance |

| 3 | Ink Ductor Roller (Web offset) | 30 | Surface strength, Shock absorption property | |

| 4 | Rider Roller | 100 | DIAMOND | Abrasion resistance, Ink transferability |

| 5 | Continuous Dampening Roller (Oil Based inks) | 20~40 | ANT COMBI | Stable water supply, Water resistance, Dimensional stability |

| 6 | Continuous Dampening Roller (UV & Oil Based Inks) | 25 ~ 30 | ANT COMBI | Stable water supply, Water resistance, Dimensional stability |

| Sr. No. | Rubber Roller | Hardness (Shore A) | Grade | Properties |

|---|---|---|---|---|

| 1 | Ink Roller (Web Offset) | 30 ~ 40 | ANT N+P | Low heat buildup, Dimensional Stability, Abrasion resistance |

| 2 | Dampening Roller | 20 ~ 50 | ANT SUPER N+P | Stable water supply, Water resistance, Dimensional stability |

| Sr. No. | Rubber Roller | Hardness (Shore A) | Grade | Properties |

|---|---|---|---|---|

| 1 | Offset Roller | 50 ~ 60 | N+P | Abrasion resistance, Ink resistance, Solvent resistance |

| 2 | Impression Roller (Paper) | 80 ~ 90 | ANT NORMAL N+P | Antistatic property, Abrasion resistance, Anti distortion |

| 3 | Impression Roller (Plastic Film) | 60~80 | ANT SUPER N+P | Antistatic, Anti distortion, Anti crack property |

| 4 | Coating Roller(Non Solvent) | 70 ~90 | W, WHITE H200, BLACK1300, 700,DYNA TITAN, TITANII, N900 | Abrasion resistance, Load resistance, Anti distortion |

| 5 | Conveyor Roller | 30 ~ 80 | 1400, M, FR, 300, WHITE EC200 | Abrasion resistance, Ozone resistance |

| 6 | Cleaning Roller | 15 ~ 30 | CLEANER, EC CLEANER | Stickiness, Antistatic property |

| 7 | Laminate Press Roller (Wet Dry) | 70 ~ 90 | 300, 700, FR, L, WHITE ST85 | Abrasion resistance, Load resistance, Ozone resistance, Anti distortion |

| 8 | Laminate Press Roller (T- die Extrusion) | 70 ~ 90 | WHITE A900, H900, N900, N900AR, BLACK EC900 | Heat resistance, High release property, Anti distortion |

| 9 | Laminate Press Roller (Non- Solvent) | 70 ~ 90 | W, WHITE H200, BLACK1300, WHITE ST85 | Abrasion resistance, Anti distortion |

| 10 | Magnetic Coating (Backup) Roller | 30 ~80 | EC700 | Conductivity, Abrasion resistance, Anti distortion |

| 11 | Emboss Roller (PVC press) | 35 ~ 80 | N900, N9005 | Heat resistance, High release property, Plasticizer resistance |

| 12 | Emboss Roller (PP, PE press) | 35 ~ 80 | 900, N1900 | Heat resistance, High releasing property |

| Sr. No. | Rubber Roller | Hardness (Shore A) | Grade | Properties |

|---|---|---|---|---|

| 1 | Spreader Roller | 40 ~ 60 | 200, 1300 | Water resistance, Abrasion resistance |

| 2 | Anvil Roller | 90 ~ 95 | 4000 | Cutting tool resistance |

| 3 | Coating Roller | 40 ~ 50 | 6000, 7000, MC, D RED 700 |

Solvent resistance, Abrasion resistance |

| 4 | Sponge Roller | TYPE-C | E-SP, C-SP | Solvent resistance, Abrasion resistance, Singular foam |

| 5 | Coating Roller | 15 ~ 50 | E-SP, C-SP | Foam uniformity |

| 6 | Offset roller | 20 ~ 50 | 6000, 7000, MC, D RED 700 |

Abrasion resistance, Ink transferability |

| Sr. No. | Rubber Roller | Hardness (Shore A) | Grade | Properties |

|---|---|---|---|---|

| 1 | Sponge Coating Roller | TYPE-C 15 ~ 50 |

E-SP, C-SP | Solvent resistance, Abrasion resistance, Singular foam, Foam uniformity |

| 2 | Coating Roller | 15 ~ 25 | Vinyl | Solvent resistance |

| Sr. No. | Rubber Roller | Hardness (Shore A) | Grade | Properties |

|---|---|---|---|---|

| 1 | Bridle Roller | 60 ~ 90 | 2000, 4000, W, TITAN, TITANII, TOUGHCELL | Abrasion resistance, Load resistance, Oil resistance, Gripping property |

| 2 | Deflector Roller | 60 ~ 90 | 2000, 4000, W, TITAN, TITANII, TOUGHCELL | Abrasion resistance, Load resistance, Oil resistance, Gripping property |

| 3 | Sink Roller | 70 ~ 75 | RC, RE, RF | Chemical resistance, Dimensional stability |

| 4 | Wringer Roller | 60 ~ 90 | RC, RE, RF, TITANII BLACK , TOUGHCELL | Chemical resistance, Abrasion resistance, Load resistance, Gripping property |

| 5 | Applicator Roller | 30 ~ 60 | MC, 6000, 7000 | Abrasion resistance, Solvent resistance, Smooth and even surface |

| 6 | Laminate Roller | 60 ~ 90 | FV, EC TITAN | Heat resistance, Abrasion resistance, Load resistance |

| Sr. No. | Rubber Roller | Hardness (Shore A) | Grade | Properties |

|---|---|---|---|---|

| 1 | Wool Washing Roller | 80 ~ 90 | BLACK285D, WHITE800, W | Water resistance, Abrasion resistance, Load resistance |

| 2 | Sizing Roller | 40 ~ 60 | 2000, 4000, W, TITAN, TITANII, TOUGHCELL | Water (glue) resistance, Abrasion resistance |

| 3 | Mangle Roller | 80 ~ 90 | WHITE800, W | Water resistance, Abrasion resistance, Load resistance |

| 4 | Turbo Stabler Perlok Roller | 80 ~ 90 | W | Abrasion resistance, Load resistance, Antistatic property |